1. Introduction to Mini Powder Coating Guns

A Mini Powder Coating Gun is a compact, handheld device designed for applying dry powder coatings to small or intricate metal surfaces. Key components include a lightweight electrostatic spray gun, small-capacity powder hopper, adjustable voltage controls, and ergonomic grips. These guns are ideal for detailed work, offering portability and precision in small-scale powder coating projects while maintaining the benefits of electrostatic adhesion.

2. Applications of Mini Powder Coating Guns

Perfect for hobbyists, jewelry makers, automotive detailing, and electronics manufacturing. They coat items like bicycle components, hardware tools, decorative metal art, and small machinery parts. Their compact size allows access to tight spaces, making them ideal for precision coating tasks on complex geometries.

3. Price Range of Mini Powder Coating Guns

Prices range from 200forbasicmanualmodelsto3,000+ for advanced systems with digital controls. Entry-level guns (200–800) suit DIYers, while professional-grade options (1,500–3,000) include features like adjustable airflow and mini powder spray efficiency.

4. Proper Use of Mini Powder Coating Guns

Clean surfaces thoroughly to remove oils or debris. Set voltage between 30–60 kV for delicate parts. Maintain a 4–8 inch spray distance to avoid overspray. Apply thin, even layers and cure parts in a small oven (250–400°F). Clean the nozzle and hopper after each use to ensure consistent mini gun performance.

5. Choosing a Mini Powder Coating Gun

Prioritize lightweight designs (under 2 lbs) for reduced fatigue. Look for adjustable voltage/airflow to handle different powders (e.g., epoxy, polyester). Check for quick-release hoppers and compatibility with compact powder coating setups. Opt for models with grounding indicators for safety.

6. Safety Tips for Mini Powder Coating Guns

Wear PPE (respirators, safety goggles) to prevent inhalation of particles. Ground the workpiece and gun to avoid electrostatic discharge. Work in ventilated areas to minimize dust exposure. Store powders in dry conditions to prevent clumping.

7. Design Advantages of Mini Powder Coating Guns

Compact and ergonomic designs enable precise control over intricate parts. Advanced models feature digital displays for real-time adjustments. Mini hoppers reduce waste, while energy-efficient electrostatic systems lower power consumption. Some guns integrate USB-C charging for portability.

8. FAQs About Mini Powder Coating Guns

Q: Can mini guns coat large surfaces?

A: Yes, but multiple passes are needed for small-scale uniform coverage.

Q: How to clean a clogged nozzle?

A: Use compressed air or a soft brush as part of routine mini gun maintenance.

Q: Are mini guns suitable for plastics?

A: Only with conductive primers or specialized powder coatings for plastics.

Q: What causes uneven coating on small parts?

A: Incorrect voltage, poor grounding, or inconsistent spray distance—calibrate mini electrostatic settings.

Q: Are these guns cost-effective for hobbyists?

A: Yes, entry-level models offer affordable precision coating solutions.

9. SEO-Optimized Keywords

Target terms: “mini powder coating gun,” “compact electrostatic spray,” “precision coating tasks,” “small-scale powder projects,” “mini powder spray efficiency,” “ergonomic powder gun,” “portable coating solutions,” “hobbyist powder coating,” “mini gun maintenance,” “electrostatic settings for small parts.”

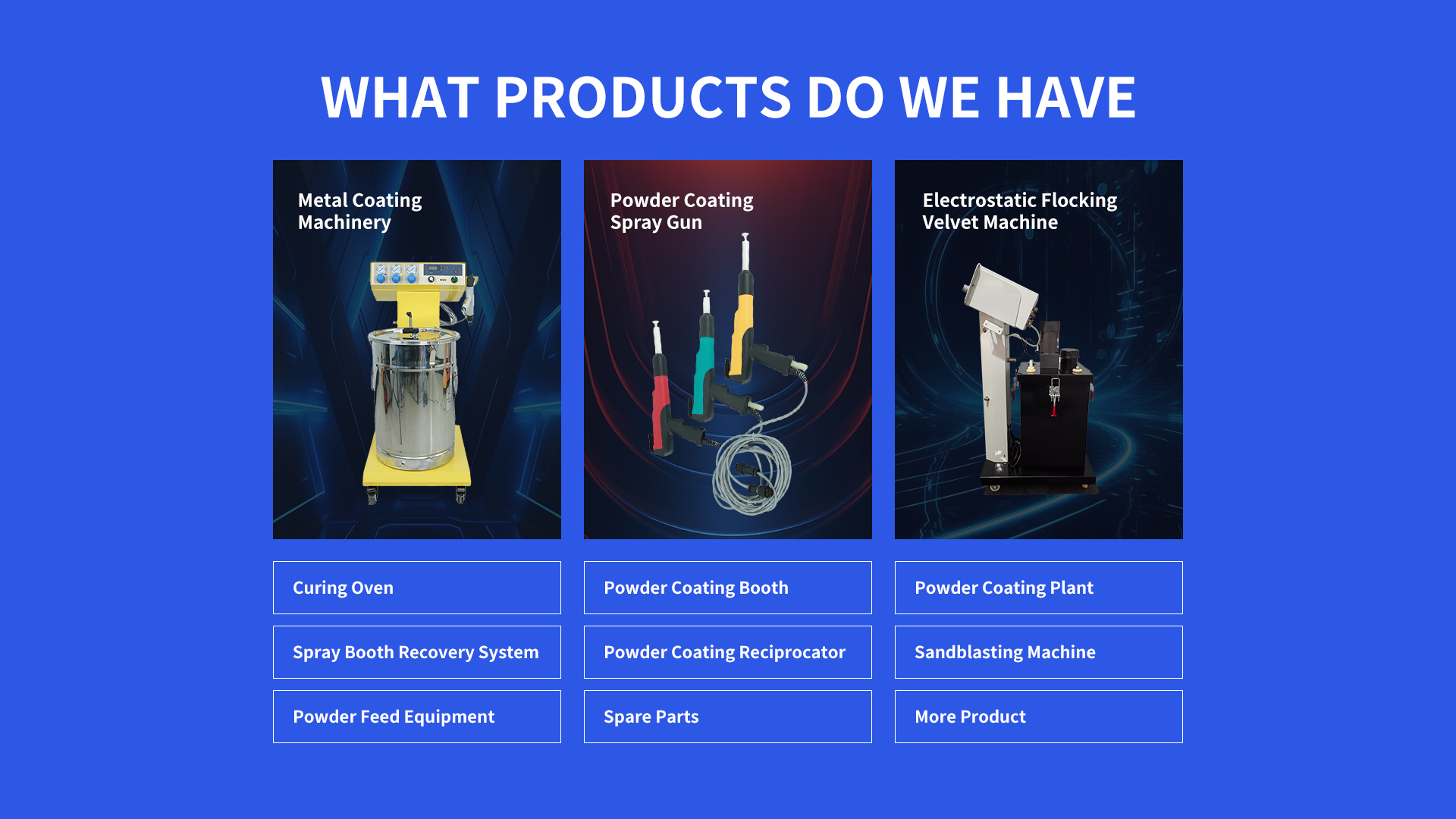

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com